Art Meets Engineering

“Working with Pocono Prototyping has been a true game changer. They transformed my 3D model into a large CNC-cut sculpture with precision and care. Their quick turnaround, excellent communication, and unwavering commitment to quality make them an invaluable collaborator in bringing creative ideas to life.”

— Darlene Farris-LaBar, Chair, Art + Media + Design Department, East Stroudsburg University

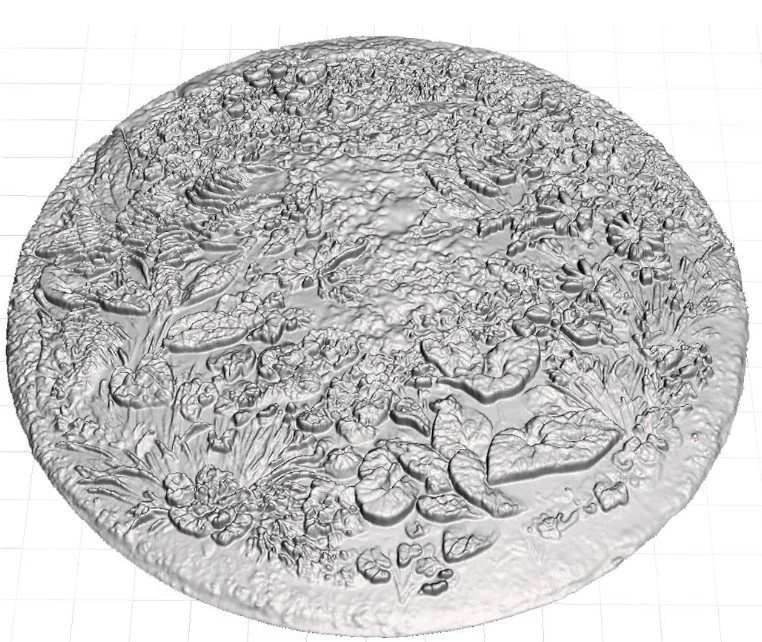

Flora Recognition by Darlene Farris-Labar as featured in the Apophenia pop up exhibition in New York

This particular project was done for a dear friend of ours, local artist and educator Darlene Farris-Labar (click here to learn about her art and background).

After launching Pocono Prototyping, we reached out to Darlene to see if she knew of anyone in the art community who might benefit from manufacturing support. As fate would have it, she was in the midst of creating Flora Recognition, her art piece soon to be showcased at the Apophenia pop up exhibition in New York with the Solstice Sisters Artist Collective.

Drawing on her deep background in floral art, Darlene chose to focus on a rare and inspiring local treasure, the Tannersville Cranberry Bog Preserve(learn more by clicking here), which is only a 15 minute drive from our shop.

A Glimpse of the Tannersville Cranberry Bog Preserve

For those that don’t know, The Tannersville Cranberry Bog, the southernmost low-elevation boreal bog on the eastern seaboard, is a rare glacial remnant that hosts unique plants and wildlife while providing vital water filtration for the Pocono Creek watershed. Protected through careful stewardship, it serves as both a cultural treasure and an educational resource for our local community.

From the the Apophenia @apophenia_saug Instagram:

“Flora Recognition by @darlenefarrislabar will be on display at the upcoming Apophenia exhibition with the incredible Solstice Sisters Artist Collective!

In a world where most people can recognize hundreds of brands and corporate logos they unfortunately cannot identify a single native plant. Come see this work in person and be part of the conversation. #FloraRecognition #Apophenia #SolsticeSisters #WomenArtistsRock #patternrecognition #WilliamGibson #darlenefarrislabar”

Pitcher Plant produced via Polyjet 3D Printing

Bog Fauna Floor Sculpture produced via CNC Mill

Bog Image produced via Lenticular Photograph

Above are the featured parts of Flora Recognition. The center piece, which is a 3D rendering of the fauna found throughout the bog is where we worked closely with Darlene to determine the best method of manufacture. An added challenging aspect of the project is that we needed to produce it in a week so she would have enough time to prep and paint the floor sculpture for the exhibition. Below you’ll see the processes and techniques we used to bring this piece of art to life with cutting edge manufacturing techniques.

Concept- 3D Model

Above you’ll see the original 3D digital rendering generated by Darlene.

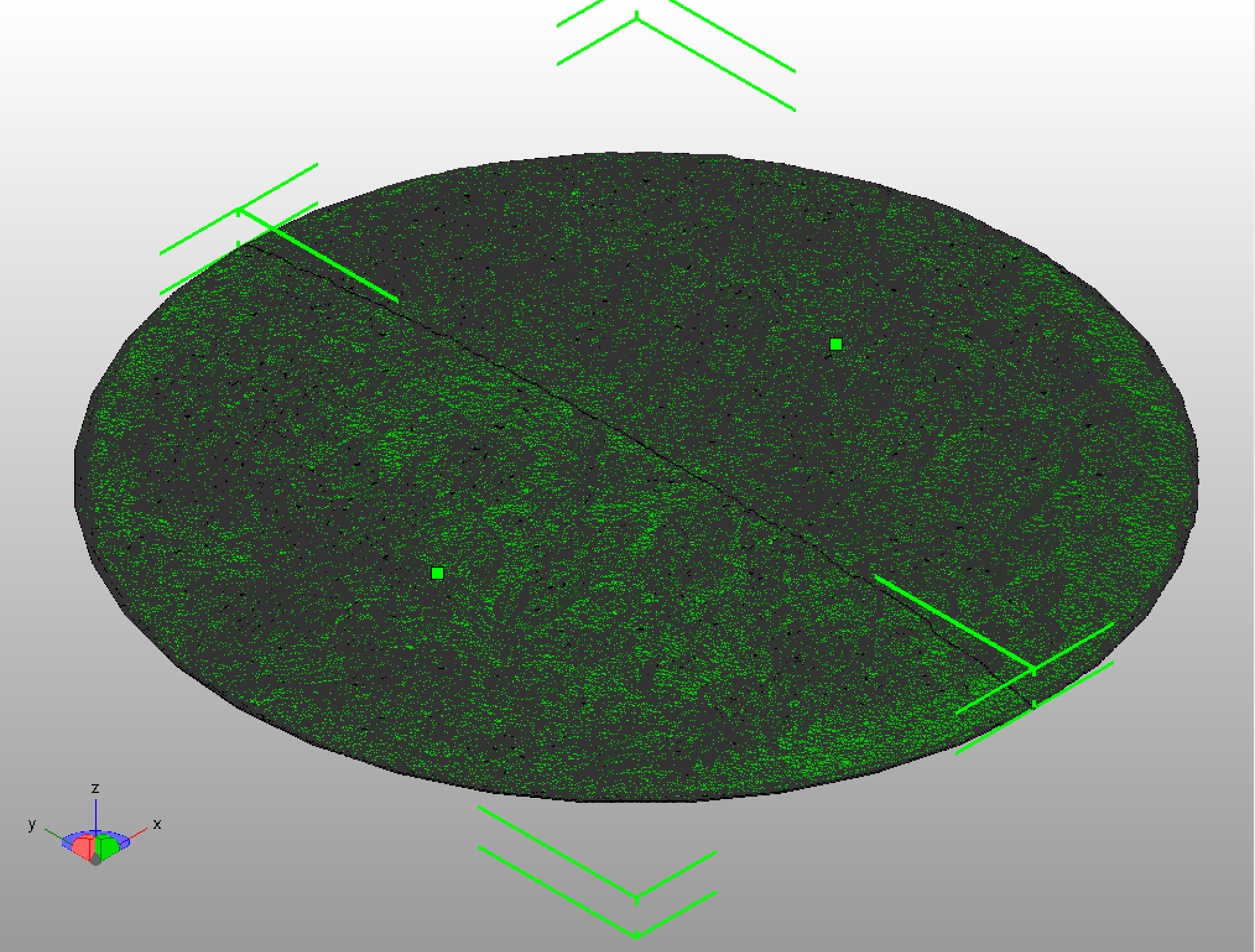

Concept- STL Mesh

Next, the 3D digital model was converted into an .STL file to be processed for manufacturing. You’ll notice how dark this image appears, that darkness is actually the lines of tens of millions of little triangles that make up this 95 Megabyte, super high resolution, .STL file.

Manufacturability - STL Mesh Refinement

95 Megabytes is huge for an .STL file and can take manufacturing software days to process. Since we were on a time constraint, we wrote software that would allow us to greatly reduce the .STL size down to only 10 Megabytes. This reduction in memory size, while significant also maintained more than enough resolution to exceed the resolution capabilities of the machine tools we used to manufacture the part.

Manufacturing - CNC Machining

After thorough discussion and decision making with our customer, we decided to produce the sculpture into two 2 foot by 2 foot sections using high density foam. This required about a day worth of machining and some hand work to accomplish. Upon completion, the parts were hand delivered to Darlene for final assembly and painting.

Delivery, Assembly & Painting

It was a busy week, from file receipt on Monday to Delivery on Friday Morning, we were pushed to the limit. Darlene shared this image with us after she completed the final painting and assembly.

This was quite the exciting project for us. Better yet, it was enjoyable working with a client that was in constant communication with our team figuring out what materials did work or didn’t work, what manufacturing process would be best, and what post processing was needed to achieve the desired result.

It’s always fun working with clients that become part of the team as we race to get them exactly what they need to be successful.