Plastic 3D Printing Innovation Backed by Metal 3D Printing

“Hey man, I really wanna say thank you for treating me so well. I know this kinda order is way less than you guys usually do but it’s been a great experience. If anything comes up where I need custom fab parts for the lab I work in, you guys are definitely the first I’ll call.”

— Nick

Metal 3D Printed Parts created at our Facility

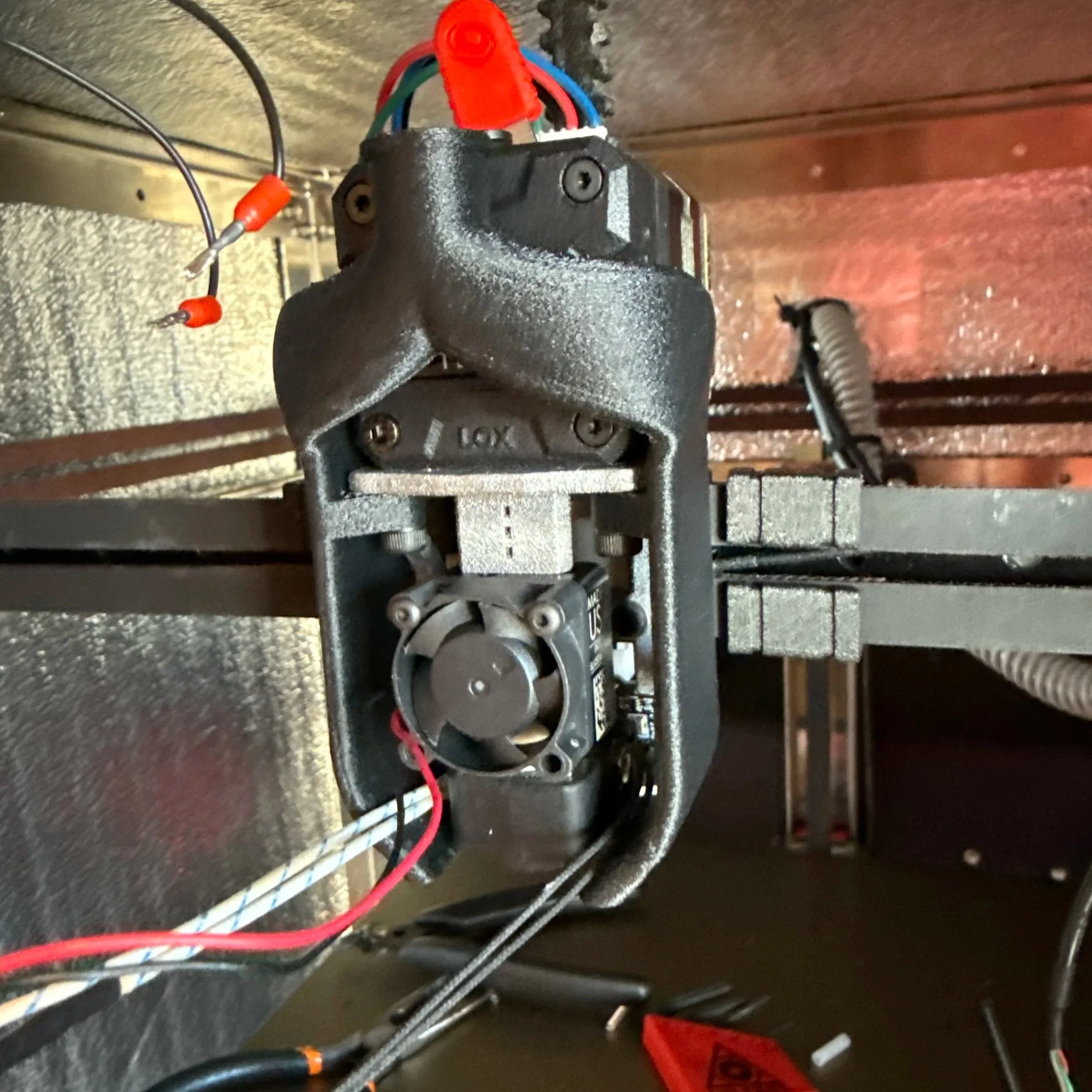

Installed Hybrid Component on Customers High Temp. 3D Printer

It was our pleasure Nick, thank you for trusting us with bringing your product to life. No matter the size of a job, we always do our best.

Nick came to us with a problem that immediately caught our attention.

He was in the middle of building a plastic 3D printer capable of processing materials at 400 °C—a temperature that pushes the limits of even the most expensive commercial plastic printers on the market. At those temperatures, most plastics don’t just degrade; they mechanically fail or melt altogether.

That created a very specific challenge: the extruder needed a carrier that could survive continuous exposure to 400 °C without failure. Plastic was off the table, which meant the carrier had to be made from metal. But there was another catch—if the printer was going to move fast and print efficiently, the extruder assembly had to stay as light as possible. Strength and weight reduction were both non-negotiable.

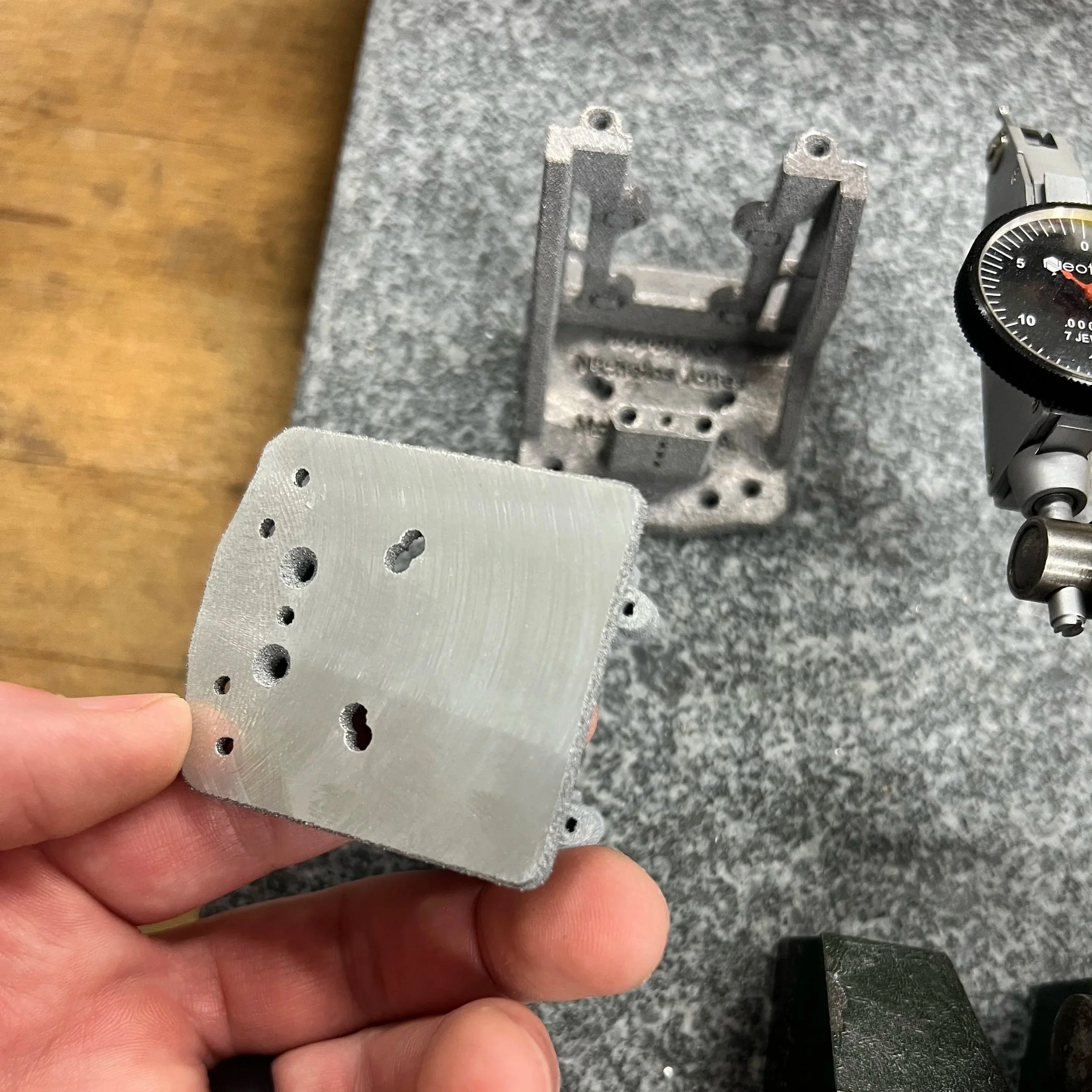

Precision CNC Machined Mounting Surface of Additive Component

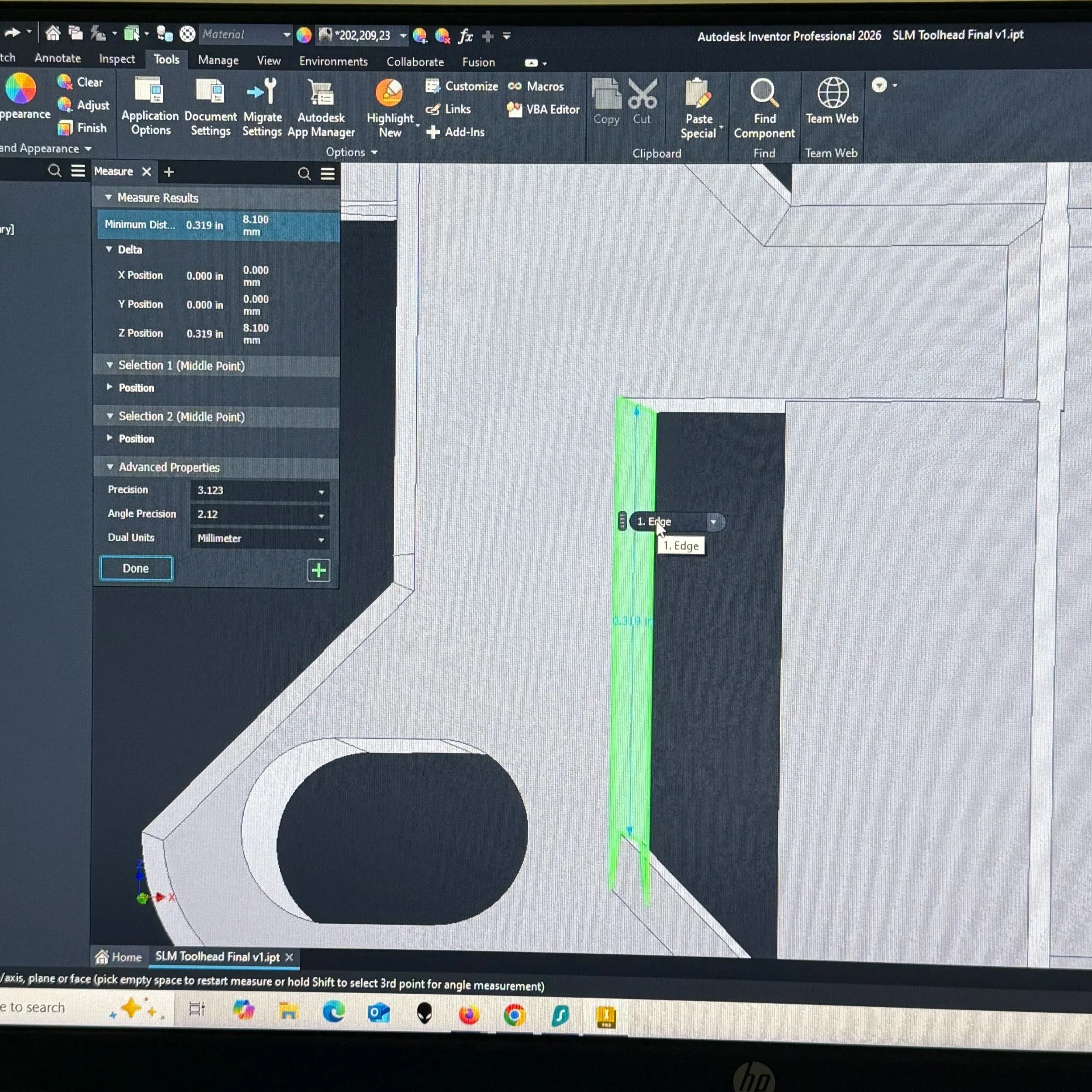

Design Review with Customer to Improve Printability

Those requirements lined up perfectly with what metal additive manufacturing does best—specifically Laser Powder Bed Fusion, the process we use to produce metal parts.

Working one-on-one with Nick, we took his initial design and refined it using our Design for Additive Manufacturing (DFAM) experience. The goal was to preserve his design intent while ensuring the part would print reliably and perform exactly as needed.

For material, we selected AlSi10Mg, an aerospace-grade aluminum alloy commonly used in satellites and advanced technical applications. It offers an excellent balance of strength, corrosion resistance, and low density—providing steel-like performance in a lightweight package.

Below you can watch a snippet of the printing process for this particular part, what you’ll see is a high powered laser liquefying microscopic metal powder into 2D shapes. This process is repeated layer by layer until a 3D object is completed.

Once the part was printed, we applied our manufacturing approach—combining metal additive with precision CNC machining technology (subtractive)—to finish the critical interface that mounts the extruder carrier to the gantry of Nick’s high-end 3D printer. This seamless blend of Additive and Subtractive manufacturing is known has Hybrid Manufacturing.

The result was a metal extruder carrier capable of handling extreme temperatures without sacrificing speed or performance—exactly what Nick needed to take his project to the next level.

If you’re facing a design problem where traditional manufacturing or materials fall short, we’d love to help—reach out and let’s see what metal additive can do for your application.