Custom Plaques

Founder Joe Sinclair Inspecting the Final Machined Surface Finish of a Machined Plaque Under Our Shop Lighting

“If there’s one thing I’ve learned as a business owner in manufacturing, it’s this: you really have one job—never let the customer down. That mindset was put to the test with a project that came across my desk recently.

We had met with a local township at our facility to discuss a large, unrelated project. The meeting went well, and after walking through our capabilities, they asked if we could help with an additional project.

They had just opened a new building and needed plaques to recognize the individuals and organizations who helped make it possible. The problem? They had placed an order with another supplier more than six months earlier and never heard back. No updates. No delivery. Nothing.

They asked if we could step in, provide a quote, and meet a firm installation deadline. We ran the numbers, aligned on the scope, and committed to the schedule. In the end, the plaques were completed and installed ahead of the promised date.

Sometimes the most important thing you can provide your customer isn’t a part or a plaque—it’s reliability.”

— Joe Sinclair, Founder

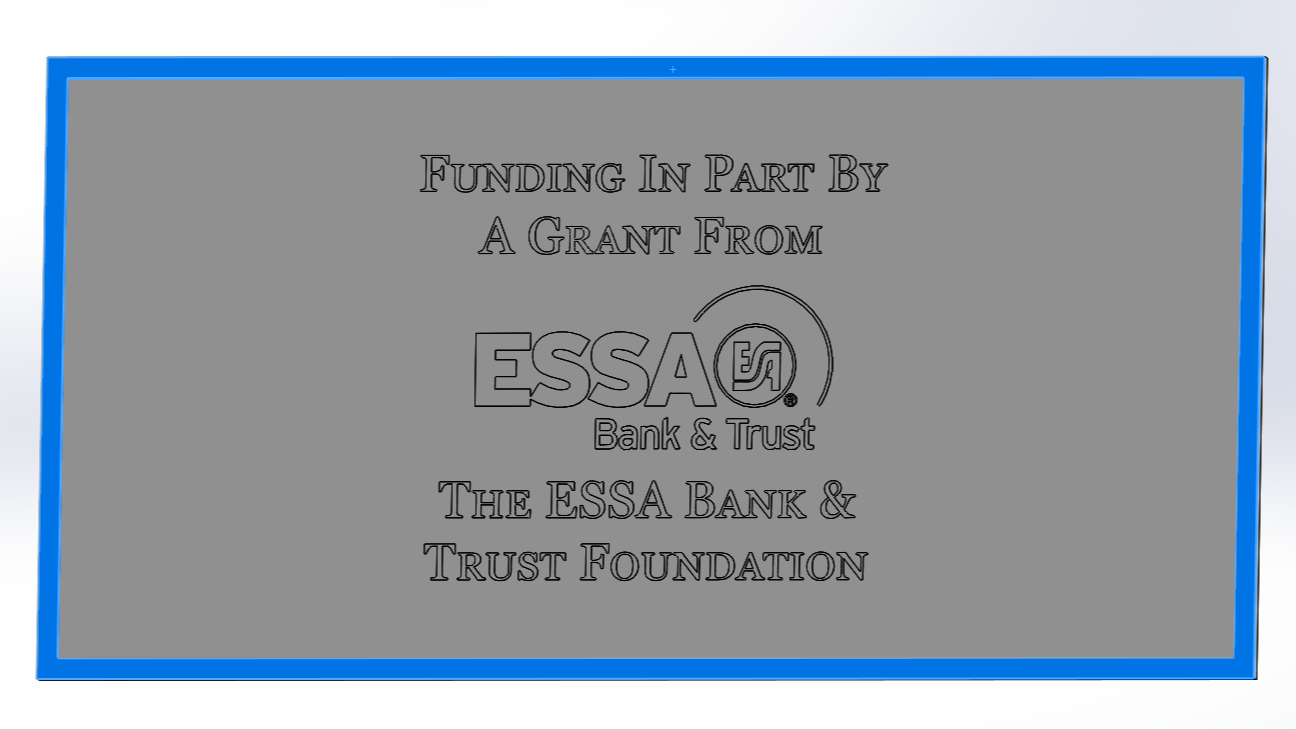

To bring these plaques to life, we first worked one-on-one with the customer to determine the contents and size for each plaque. Taking that information, we used our computer aided design (CAD) software to generate 3D models of each plaque.

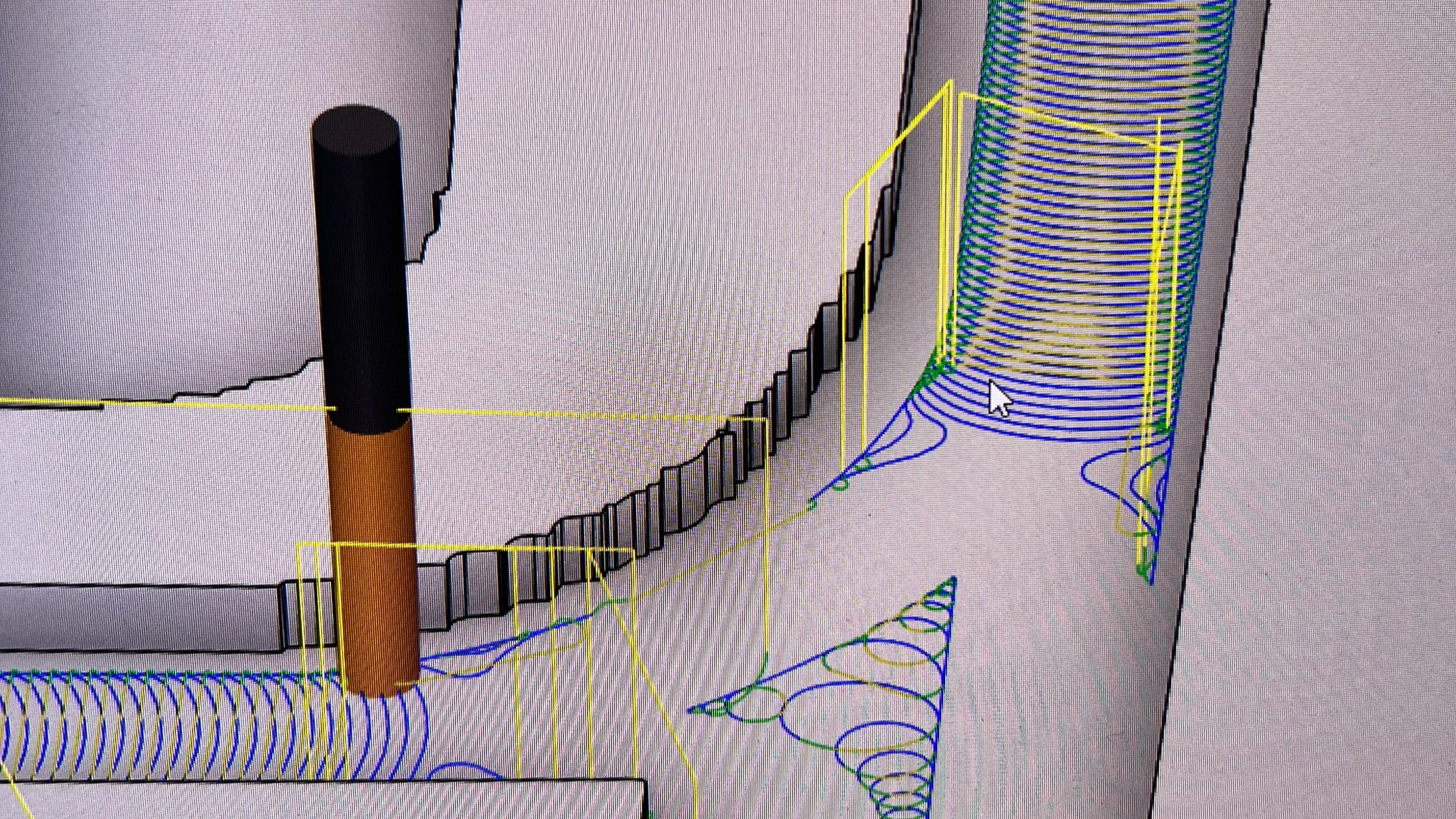

Next, we took these 3D models and opened them in our computer aided manufacturing (CAM) program to generate tool paths and determine what tools and material size would be required to fabricate them to our customer’s specification.

3D CAD Plaque Model

CAM Generated Program for Plaque Model

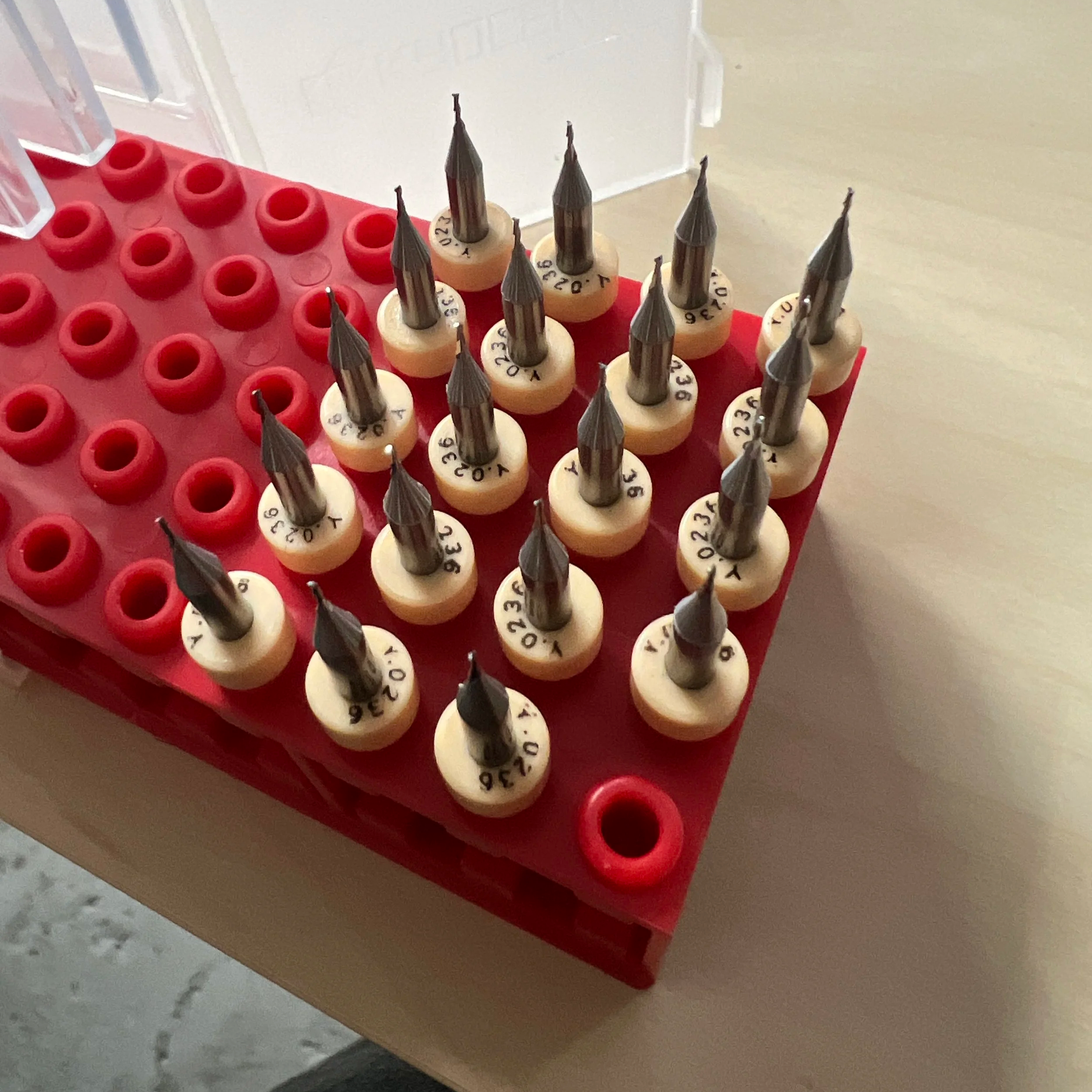

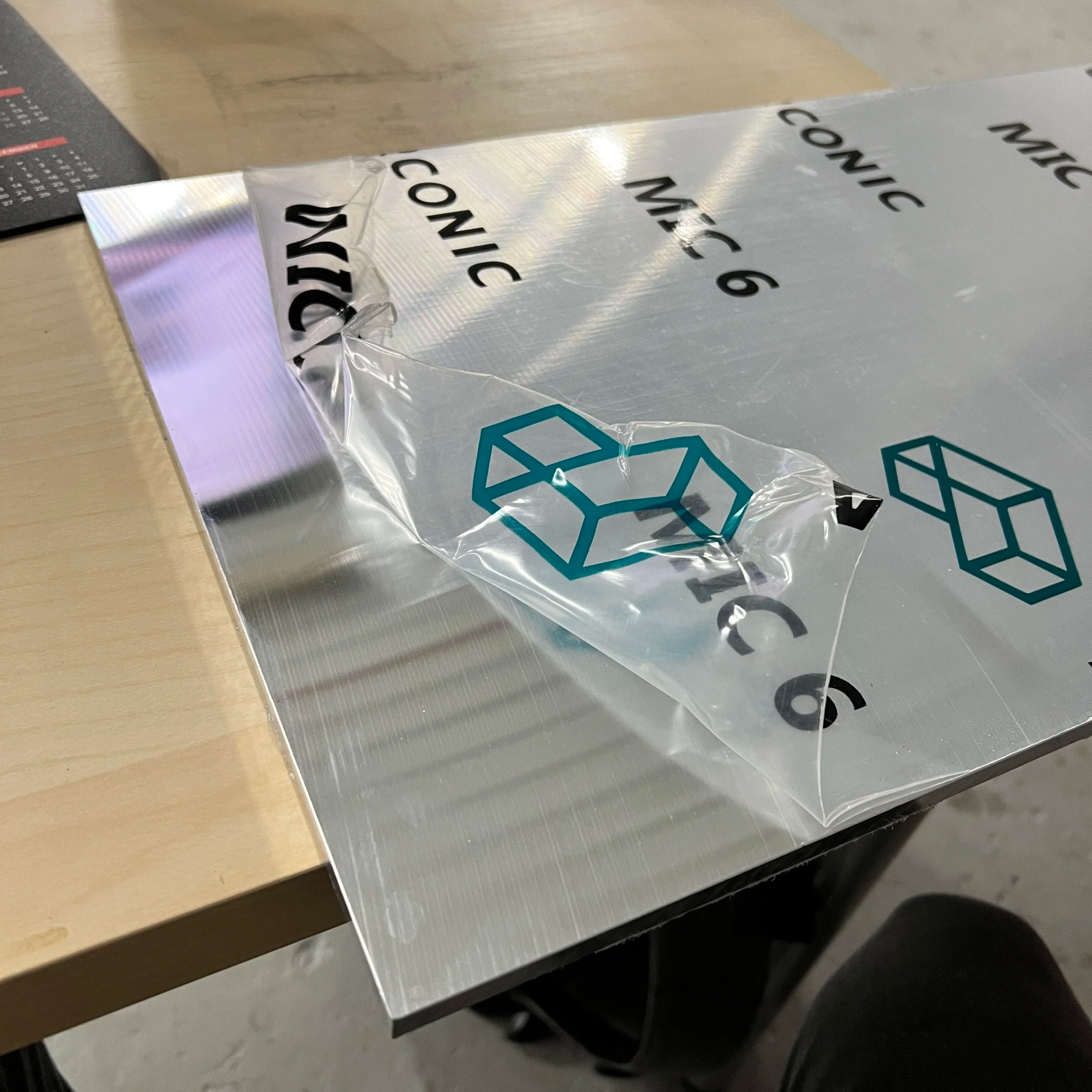

After generating the CAM data, we ordered specialized tooling and material. For material we opted for cast aluminum plate, the reason being that cast aluminum plate is much more stable when being machined where as other methods of aluminum material production can generate internal stresses that allow the material to warp once machined. To maintain ultra flatness post machining, cast plate is the only way to go.

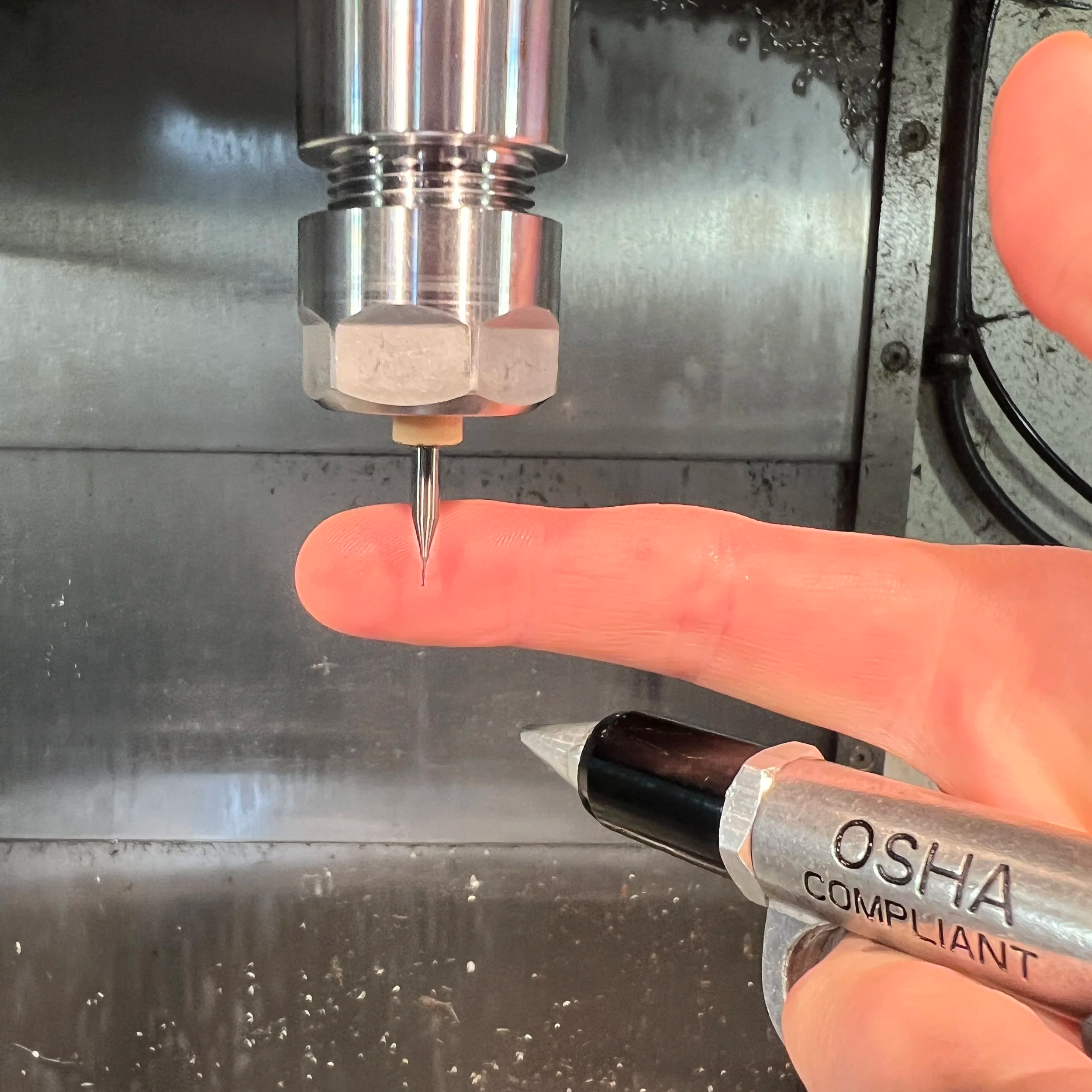

.0236” Diameter 3 Flute End Mills for Final Finish Machining

Sense of Size for Finishing End Mill

MIC-6 Cast Aluminum Tooling Plate

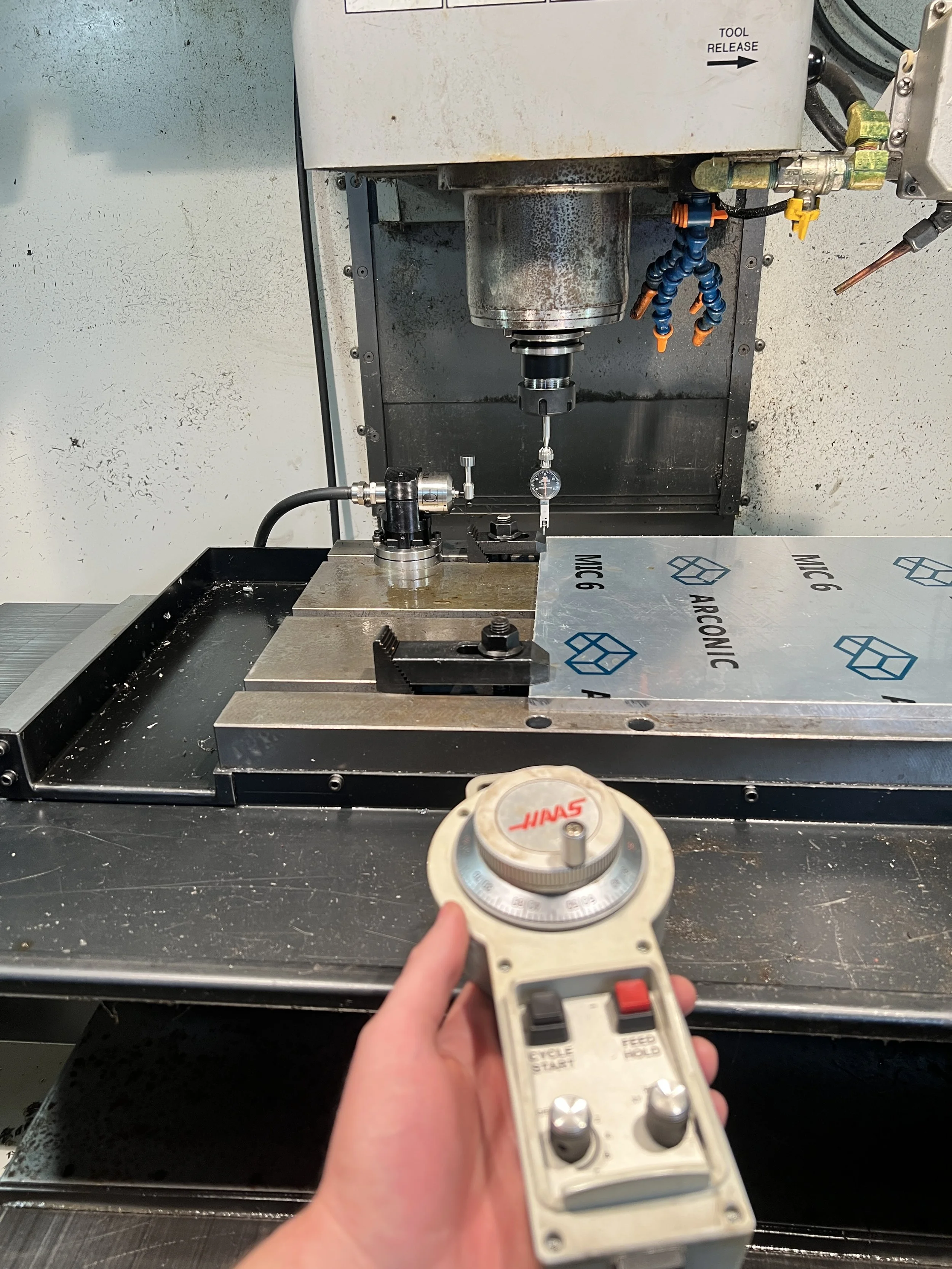

Once we secured our tooling and material, we setup our computer numerically controlled (CNC) machining center, touched off our tools, checked our tool clearances with our clamps, and loaded the programs.

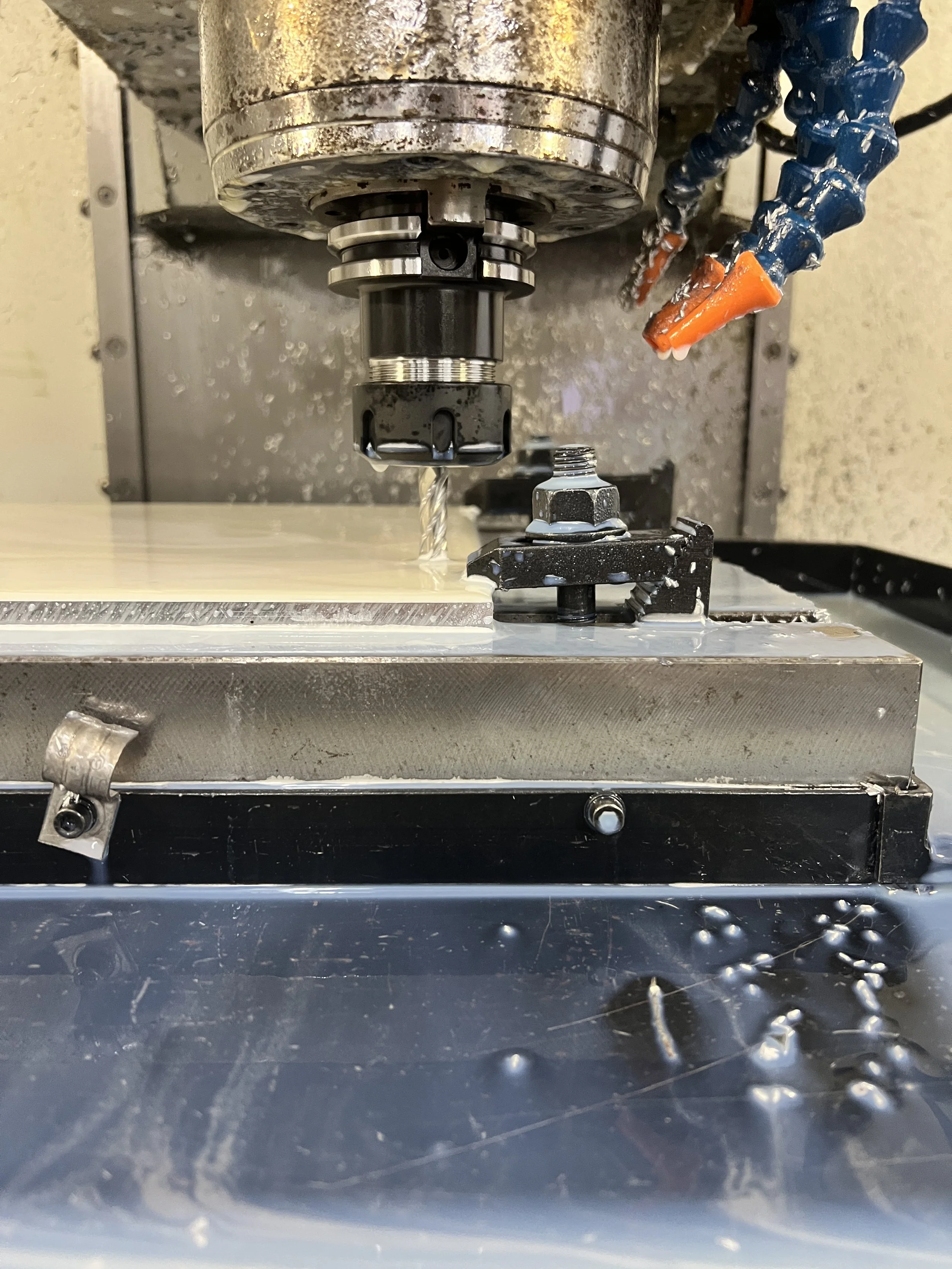

Then we were onto machining. Below are snapshots and video of the machining process for the plaques. Once machined, we carefully hand deburred each plaque to ensure maximum paint adhesion.

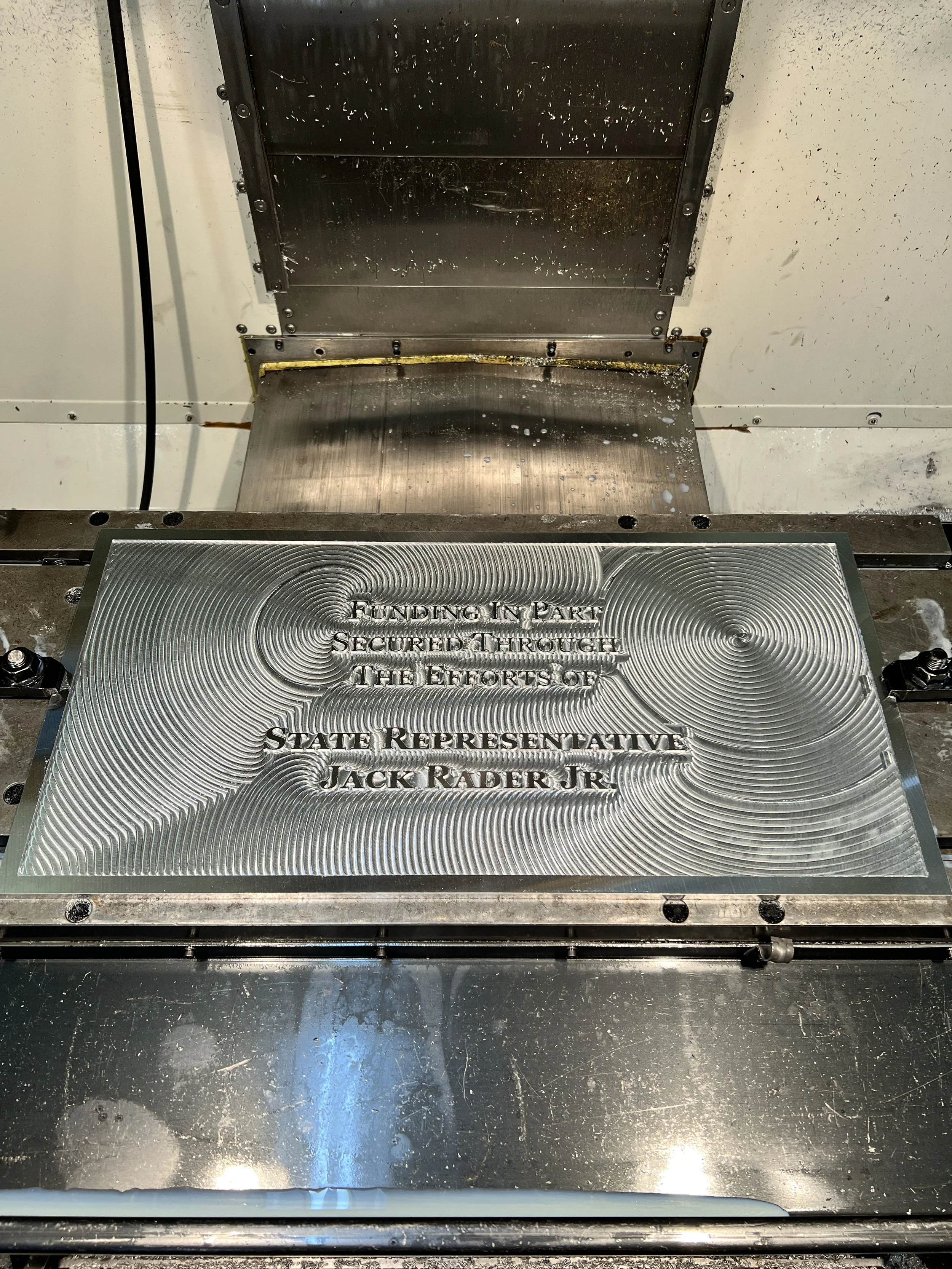

Plaque As Machined on Our CNC

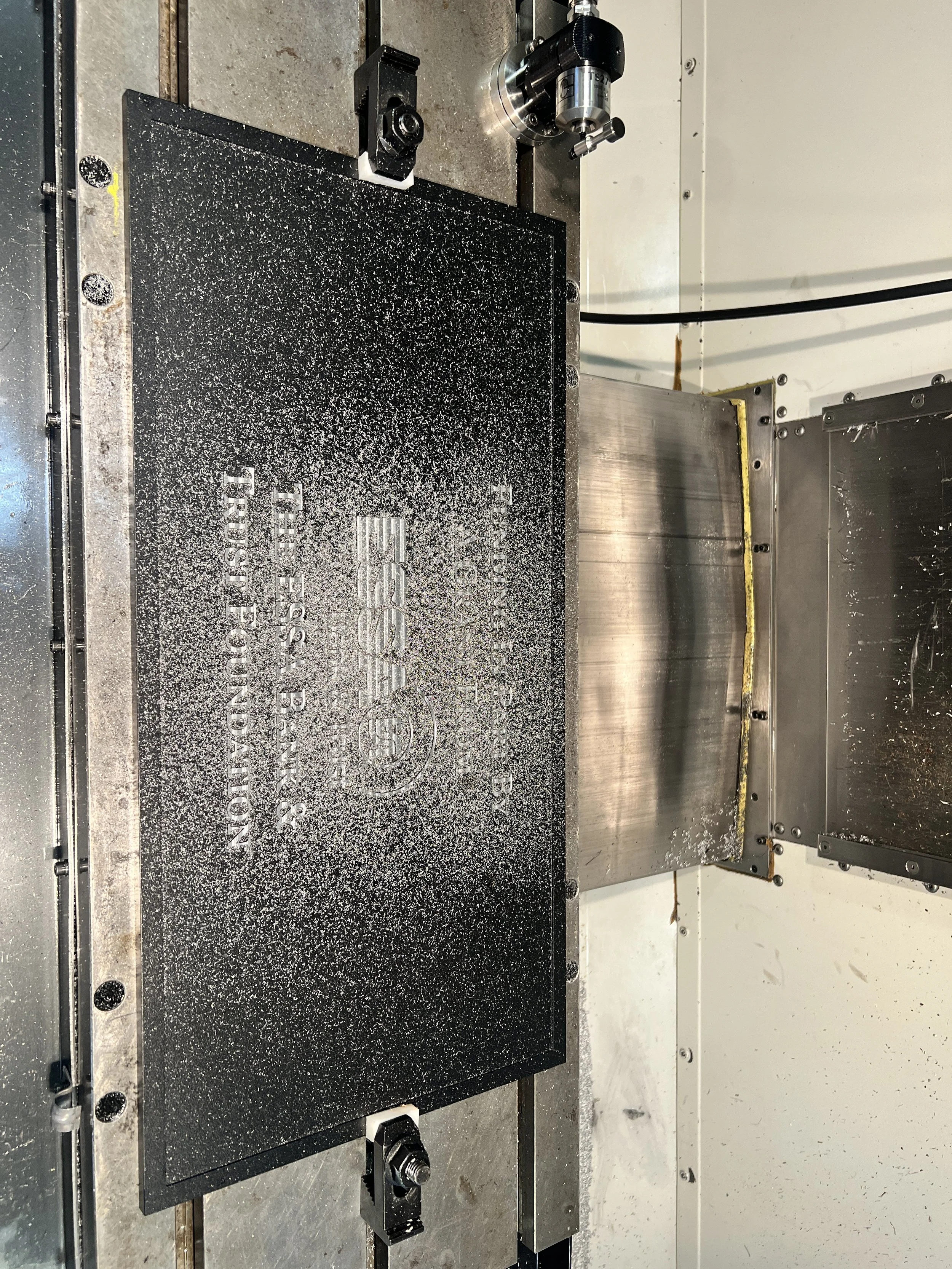

Lights Out Manufacturing at Our Shop

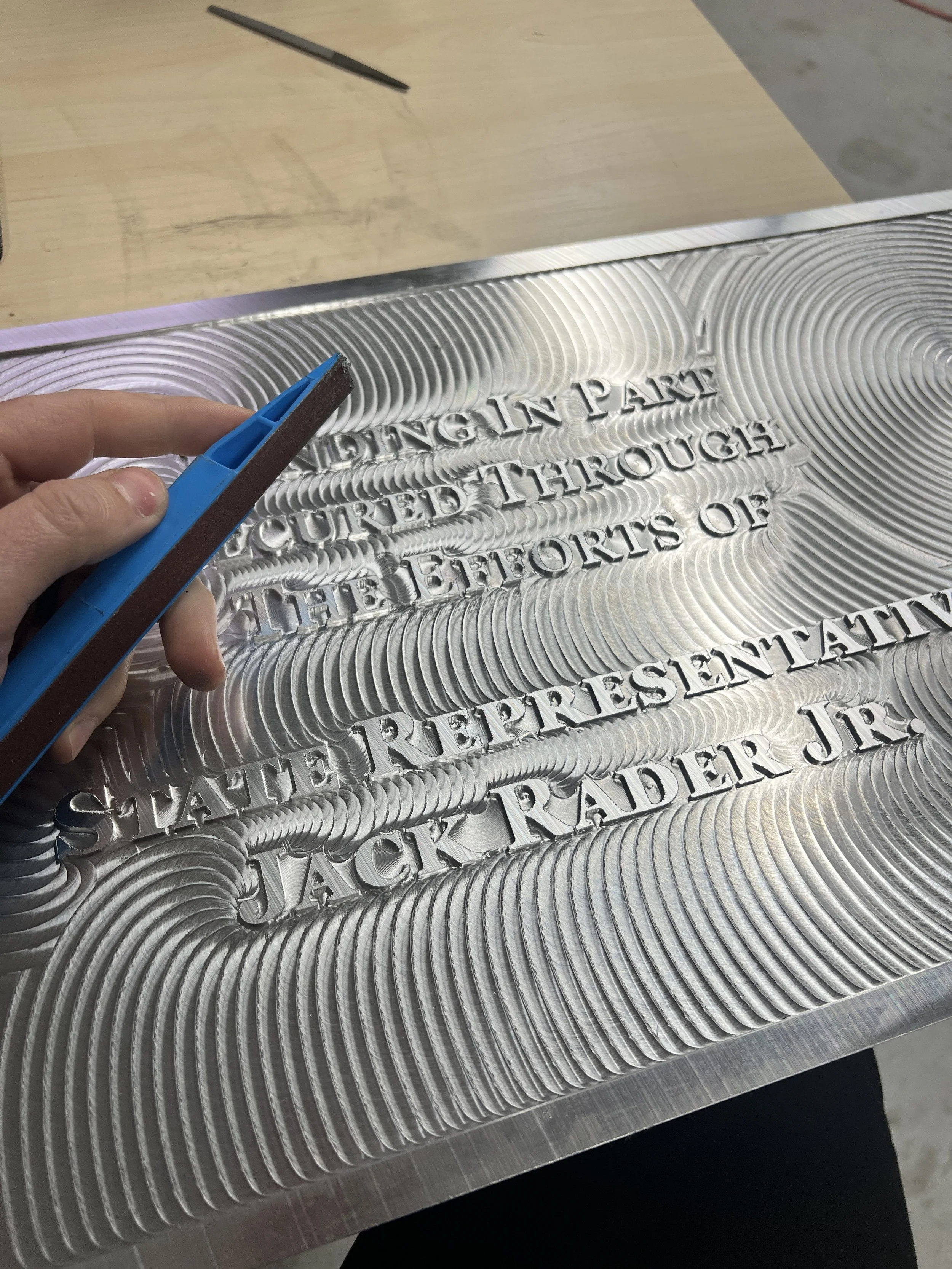

Deburring Prior to Paint

Machined Plaques Ready for Painting

After all the plaques were final machined, we prepared them for plating. The customer already had another plaque on site they wanted to paint match, so we took a few photos and worked side by side with our painting vendor to discern the best match. After inspecting and receiving the plaques back from plating, we re-set up the plates in the machine for the final face cut which removed a few thousands of paint & material to re-expose the shiny bare aluminum surface. In the below image, you can see us using a .002” (two thousandths of an inch) feeler gauge to ensure proper depth of cut.

Machined Plaques After Paint

Verifying Depth of Cut with .002” Feeler Gauge

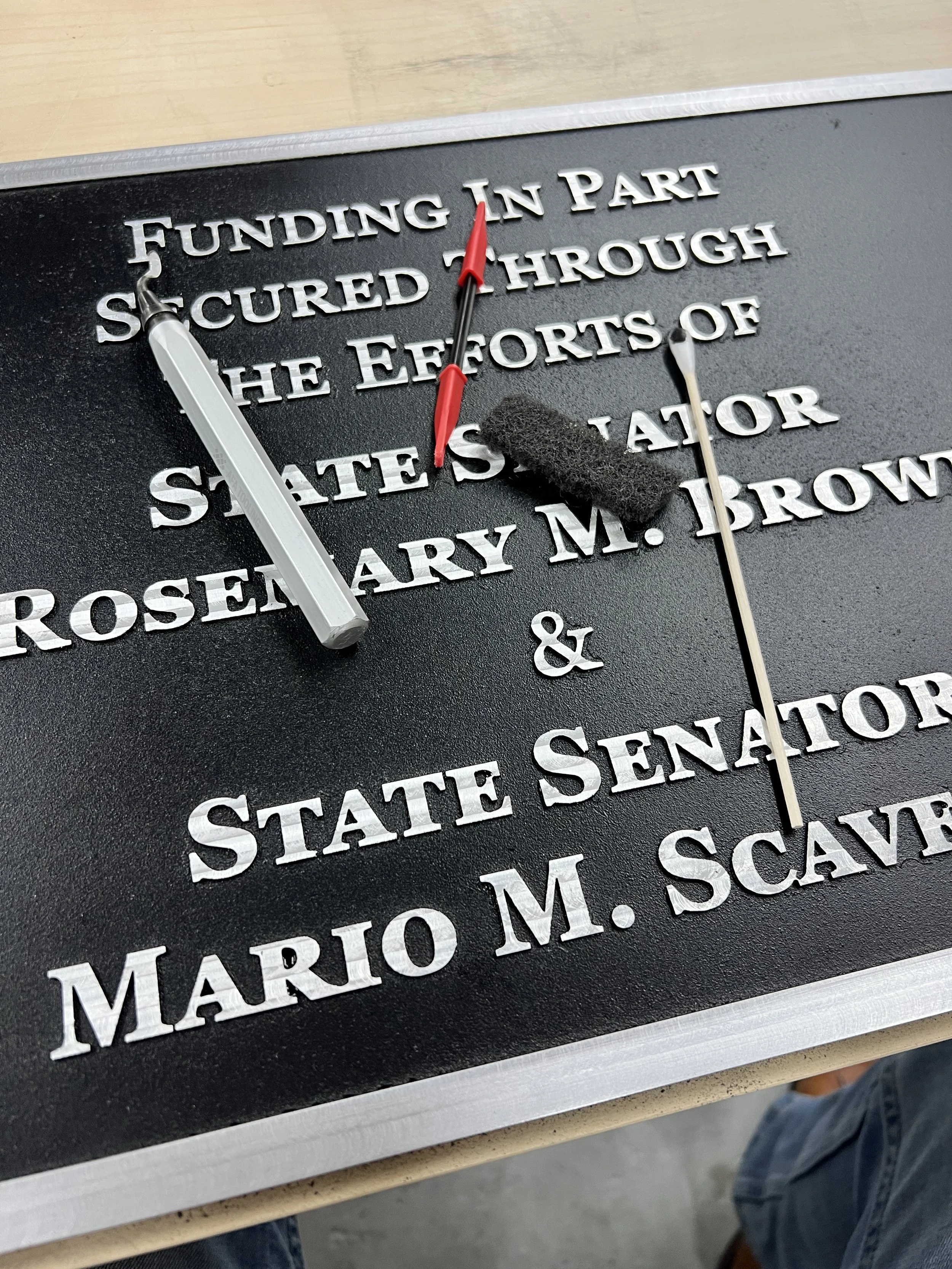

This next phase was the ‘pucker factor’ phase, which means to say, a tremendous amount of time and value add is contained within these parts. Any mistake at this point significantly increases the cost to remake the parts. Fortunately, through patience and using the “measure twice, cut once” mindset, we were able to successfully machine all the plaques and deburr them in preparation for customer delivery. Below are a few photos walking you through the different processes required to finalize these plaques.

Final Machining Operation

Deburring Plaques prior to Customer Delivery

Manual Machining for Fastener Through Hole Locations

Deburring of Fastener Through Holes

Test Fitment of Mounting Fasteners

Completion of Plaques

Delivery Preperations

Installation

Without further ado, here is the final result and the customer couldn’t be happier.

Finished and Installed Custom Plaques for Our Customer